About Me

Mechanical Engineering graduate with a strong foundation in maintenance, reliability, and mechanical design. Experienced in working with piping systems, P&IDs, PFDs, and isometric drawings. Proficient in preventive maintenance planning, spare parts management, and asset tracking using Limble CMMS. Supported chemical offloading systems and Pre-Start Health and Safety Reviews (PSR) through hands-on field inspections and documentation updates.

Skilled in automation and controls, including PLC programming, embedded systems (Arduino, Raspberry Pi), and electro-pneumatic integration. Technically proficient in SolidWorks, AutoCAD, SAP, MATLAB, Python, and the Microsoft Office Suite. Known for strong communication, organization, and problem-solving abilities, with a collaborative approach to engineering challenges and cross-functional teamwork.

Education

Bachelor of Engineering, Mechanical Engineering, specialization in Mechatronics

Toronto Metropolitan University

Courses: Fluid Dynamics, Thermodynamics and Heat Transfer, Statics and Strength of Materials, Digital Systems, Dynamics, Electric Circuits, Digital Computation and Programming, Manufacturing Fundamentals

Work Experience

Reliability Engineering Intern

VPC Group Inc.

- Assisted in the implementation of a tote-based chemical offloading system aligned with Pre-Start Health and Safety Review (PSR) requirements under Ontario Regulation 851.

- Reviewed and updated P&IDs (Piping & Instrumentation Diagrams) to reflect current piping configurations and support future safety/maintenance assessments.

- Reviewed rack system certifications and safety documentation for compliance with CSA S136, S345, and A344 standards during the implementation of a tote-based chemical offloading system.

- Analyzed MSDS sheets, PPE requirements, and spill containment procedures as part of chemical safety planning and compliance efforts.

- Collaborated with engineers and contractors during installation/commissioning phases and supported Joint Health & Safety Committee (JHSC) documentation.

- Verified field conditions against piping layouts and CMMS data to identify documentation gaps and support reliability updates.

Maintenance Engineering Intern

VPC Group Inc.

- Managed preventive maintenance programs across 15 sites using Limble CMMS, scheduling inspections, automating recurring tasks, and tracking asset history to minimize equipment downtime.

- Digitized and organized spare parts inventory by identifying critical components, assigning storage locations, and integrating associated bill of materials with minimum stock levels into Limble.

- Integrated new production lines into CMMS by creating preventive maintenance schedules, registering equipment, and linking spare parts to support servicing workflows.

- Analyzed inspection trends and maintenance history within Limble CMMS to identify recurring faults in motors, belts, and sensors, supporting audit readiness and proactive servicing.

- Verified equipment condition and spare part requirements during field walkthroughs for preventive maintenance tasks, ensuring CMMS records matched actual site conditions.

Projects

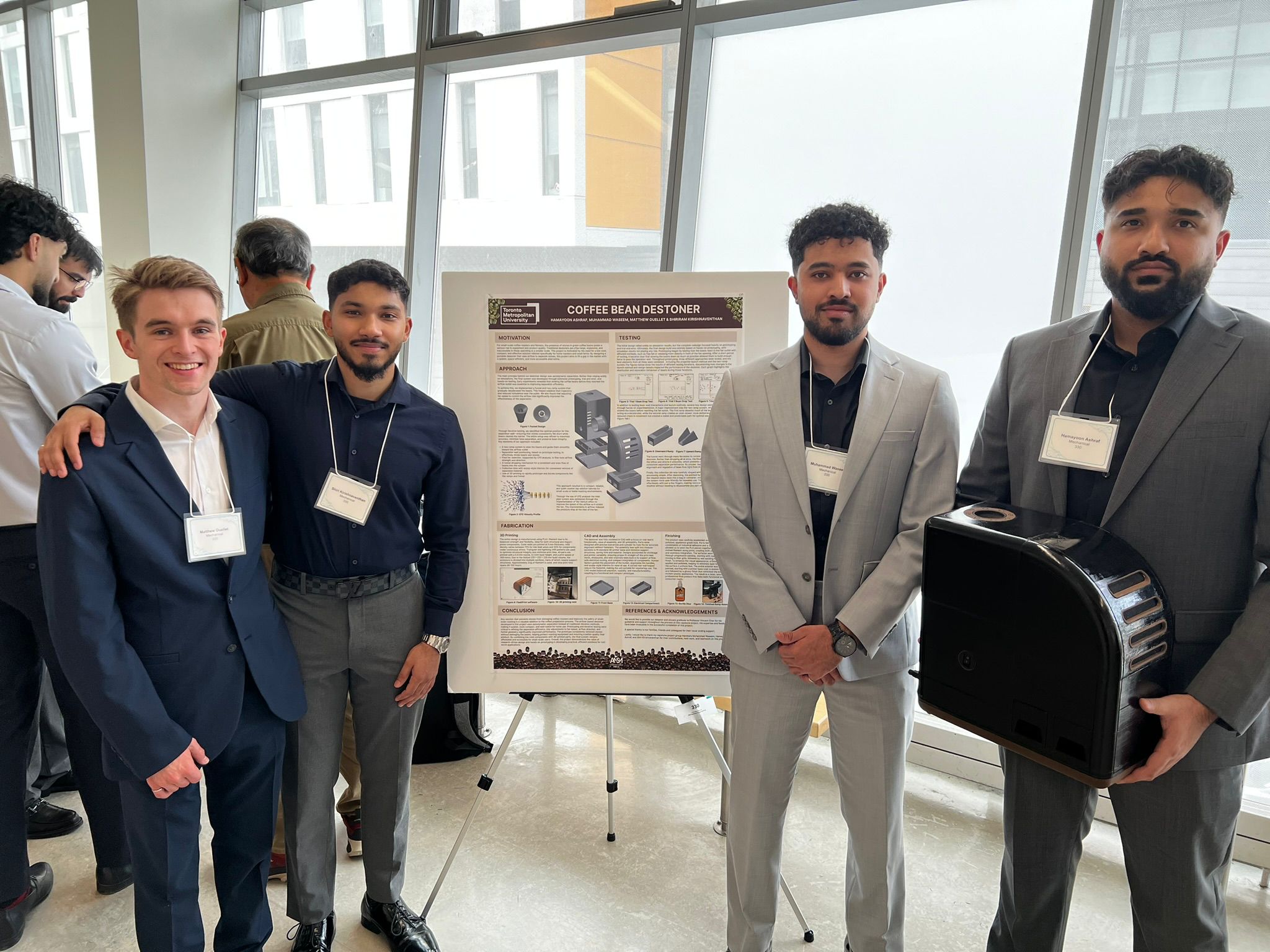

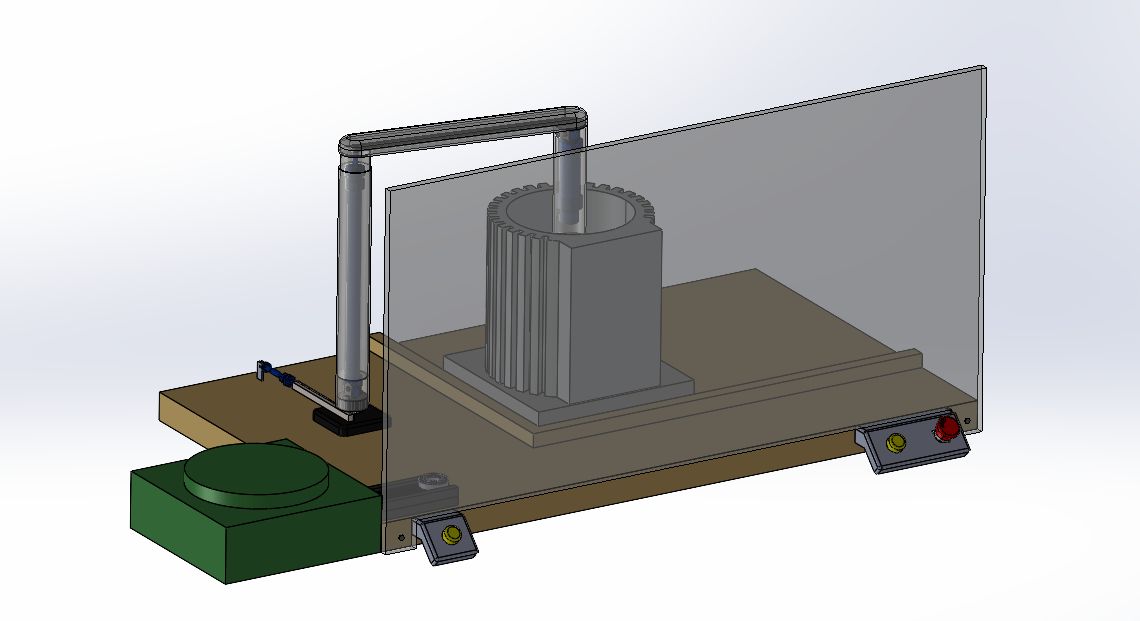

Coffee Bean Destoner – 3D CAD Modeling & Electro-Mechanical Prototyping

- Designed a functional coffee bean destoner to separate stones from beans, creating 3D models and engineering drawings in SolidWorks, applying GD&T and fit tolerances to ensure 3D printability.

- Fabricated prototype components using PLA+ filament and snap-fit joints, performing iterative adjustments based on fit testing and dimensional deviations.

- Collaborated with teammates to integrate mechanical, electrical, and control systems, contributing to part alignment and system packaging during assembly.

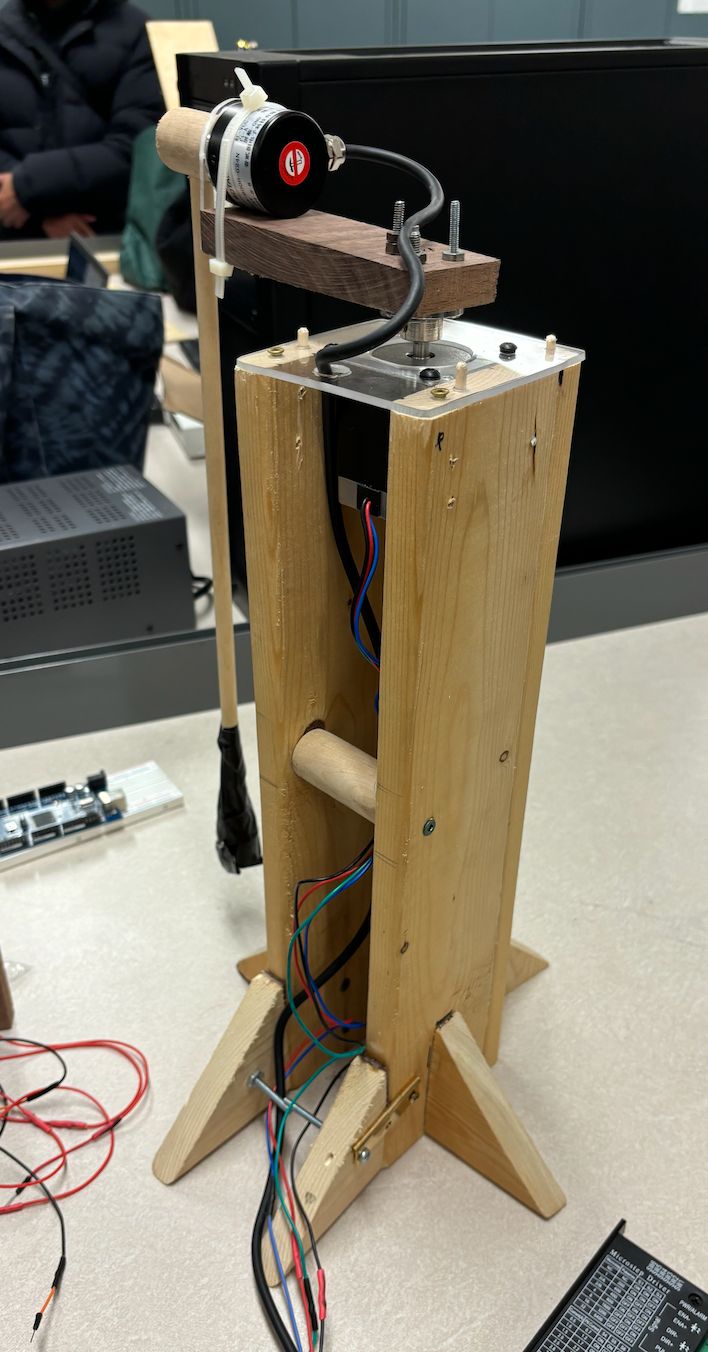

Motor Housing Bearing Installer – Pneumatic Systems & PLC Integration

- Designed and built an autonomous electro-pneumatic system for press-fitting motor bearings, prioritizing operator safety using a dual push-button circuit compliant with OSHA machine safeguarding standards.

- Programmed a PLC to control pneumatic actuators for bearing insertion, achieving a consistent 30-second cycle time and meeting all functional and timing requirements.

- Integrated limit sensors and interlocks to ensure safe operation, and collaborated with team members on troubleshooting control logic and system reliability.

VisionX – Assistive Device for Visual Impairment (Hackathon Project)

- Led a 4-member team at DeltaHacks 6 to develop a wearable obstacle-detection device for visually impaired users by integrating ultrasonic sensors.

- Designed the 3D-printed enclosure and organized internal component layout for compact wiring and sensor placement.

- Wrote Python scripts on a Raspberry Pi to process real-time distance data and control haptic feedback alerts.

Self-Balancing Pendulum – Real-Time Control System Design

- Built a real-time control system for a self-balancing pendulum using embedded sensors, actuators, and microcontroller-based PID and pole-placement algorithms.

- Performed fault modeling and risk analysis using FMEA and Fishbone diagrams, identifying failure modes and integrating safety features into the mechanical and electrical design.

- Designed an HMI panel and implemented responsive control logic, using bottom-up and top-down reasoning to optimize system maintainability, signal filtering, and user interface layout.